Did you know many companies have been successful thanks to nearshoring their manufacturing operations?

Here’s the problem you face: your manufacturing and logistics costs are on the rise as well as the delivery times of your products to your final customers.

This means you’re losing competitiveness; your margins are shrinking and you’re being unable to keep up with your competitors.

Luckily for you, there’s a solution. We introduce you to the 5 Nearshoring Challenges so you can overcome your cost concerns and focus your time and energy on growing your margins and market share.

Lower your costs with qualified labor in a country with a demographic bonus so you can be and remain competitive. Expand operations to a country with thriving commercial treaties with the USA so you can take the advantages that come attached to these relationships which means more benefits for your company. Select a strategic location that helps lower your logistic costs and times so your product can reach your customers faster which means more efficient fulfillment times.

For over 35 years, we’ve been assisting more than 700 foreign investors in the manufacturing industry taking the advantages of nearshoring their operations to Mexico.

5 Challenges to Nearshoring in Mexico

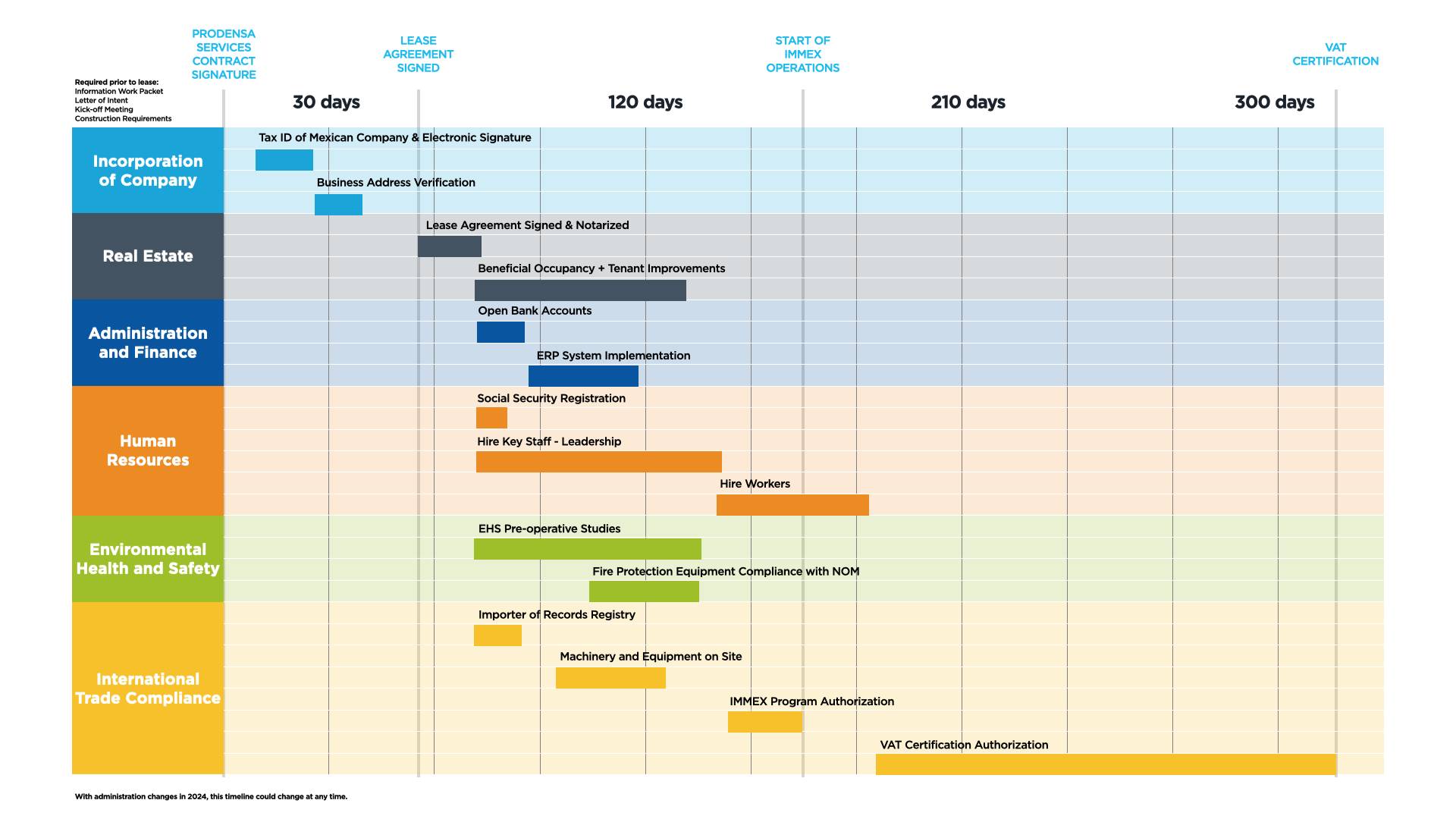

Mexican Regulatory Compliance

Mexican Regulatory Compliance

Don’t Lose Sight of Compliance

Ensure local compliance in your operations. No matter what country you operate, governments are also being squeezed, and their interest to attract investment usually translates to game changes as well. You can’t focus only on global macros and dismiss the changes to incentives and rules that could add up to even more headaches and costs. One can’t go without the other.

Manufacturing Compliance Regulations in Mexico:

-

Official Mexican Standards (NOMs)

-

Federal Labor Law (Secretary of Labor)

-

Social Security (IMSS)

-

IMMEX (Maquiladora, Manufacturing and Export Services Industry)

-

USMCA (United States-Mexico-Canada Agreement)

-

Maquiladora VAT Certification

-

Rule of Origin (RoO)

-

International Organization for Standards (ISO)

Ramp-Up Costs (Investment)

Ramp-Up Costs (Investment)

First, analyze how much it costs to open a new manufacturing facility. These are some costs we recommend being considered in the decision-making process.

Labor: The sum of all wages paid to employees, employee benefits (mandatory and market-driven), and payroll taxes paid by an employer.

Logistics: Supply chain, transportation, tariffs, import duties, and other associated costs.

Infrastructure: Land, building, and utilities (electricity, water, natural and industrial gas, fiber optics, and other).

Services: Fixed costs, variable costs, operating costs, maintenance.

Taxes: Taxes and fiscal obligations on federal, state, and local levels. How to adjust your Mexico tax strategy to your corporate vision.

Government Incentives: Governments can offer financial assistance to private businesses making investments using economic incentives. Incentives can include tax abatements, tax revenue sharing, grants, infrastructure assistance, no or low-interest financing, free land, tax credits, and other financial resources. The Mexican government has also announced specific nearshoring incentives for companies investing and supporting their development strategy.

Adapting Company Culture to Mexico

Adapting Company Culture to Mexico

Successfully adapting your company culture to the local environment is imperative for long-term success when doing business in Mexico. A culturally aligned workplace fosters stronger employee engagement, reduces turnover, and supports a smooth integration of global business practices with local customs.

To become an employer of choice, it’s essential to understand regional values, communication styles, and community expectations. Companies that embrace cultural nuances are better equipped to build trust, improve workforce morale, and drive sustainable performance.

Case in Point: One of our international clients successfully localized their company culture by engaging local leadership, offering career growth programs, and aligning HR practices with Mexican labor values. Within two years, they were recognized as an employer of choice in their region, significantly improving retention and productivity.

👉 Becoming an Employer of Choice in Mexico

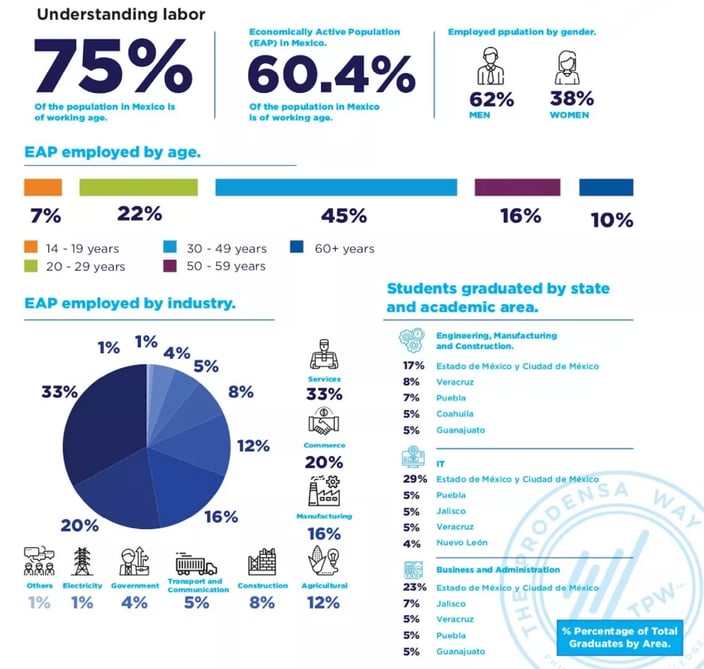

Labor

Labor

Finding, attracting, and retaining the right workforce is essential when expanding operations. Among the challenges to nearshoring is navigating Mexico's labor landscape, which includes understanding regional salary structures, competitive benefits, legal obligations, and workforce availability.

Companies must also build effective HR strategies that resonate with local talent, invest in training and upskilling initiatives, and ensure compliance with Mexican labor laws. Developing a strong employer brand can significantly improve hiring outcomes and reduce turnover.

Strategic Advantage: Establishing partnerships with experienced local recruiters, tapping into educational institutions, and aligning job roles with community expectations will allow companies to create a stable and motivated workforce, enhancing productivity and reducing onboarding risks.

Identifying the Supply Chain

Identifying the Supply Chain

Developing a business case and conducting scenario planning are key strategies for successful nearshoring, allowing companies to optimize their supply chains and increase competitiveness. Applying a multi-factor assessment to analyze cost, volume, standardization, value risk, etc., to your supplier network will give the foundation for scenario-planning and network optimization that will increase competitiveness.

Relocating or Developing Supply Chains

If you currently have a supply base in China, evaluate what options you may currently have for supply chain agility. Consider the necessity to bring suppliers to North America or develop local, existing supply bases in key-value chain areas.

👉 Strengthening Supply Chains through Strategic Vendor Identification

👉 Identifying Suppliers for Nearshoring - From Asia to Mexico

We have multiple clients pursuing options for flexible and secondary supply chains, investing in feasibility studies for multiple supply chain alternatives, to see what options they have. It’s not enough to evaluate current market situations like taxes and tariffs and try to adapt to current market situations. You must develop multiple scenarios because the global market is in constant and accelerated change.

Supply Chain Diversification

It’s extremely risky to rely on just one provider. We have seen entire value chain shifts from the impacts of just one company’s decision to relocate. When a key provider must make tough decisions for survival, it’s definitely going to affect others. If you rely on a limited supply base, you put yourself at risk, even if you maintain great relationships. Identifying alternatives, such as nearshoring, is the only way to be agile and proactive in today’s market, and that is translating to competitiveness among global companies.

About Prodensa: your Nearshoring Partner

With 40 years of experience, GRUPO PRODENSA has been involved in start up operations and shelter in Mexico. We have assisted over 1,000 projects from all kinds of industries.

If you are interested to know more about nearshoring your supply chain to Mexico or understanding the challenges of doing business in Mexico, contact us. We would love to assist you.

Download the free Nearshoring your Supply Chain to Mexico e-book.